Projects - Avonmouth Pre-Purification Unit Controls Upgrade

Tierney Strachan replaces Transco LNG Storage Avonmouth PPU Control System

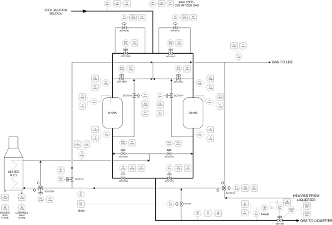

CO2 must be removed from natural gas before liquifaction to avoid solids forming within pipework and process equipment. At the Transco LNG Storage Avonmouth Facility, this is performed in a two-stage process starting with a Selexol system and followed by a Pre-Purification Unit (PPU). The PPU consists of two CO2 adsorbing towers operating in a continuous process. Generally, one tower is on-line and treating the feed gas at any time, with the other tower going through the regeneration process to remove the adsorbed CO2.

The previous PPU control system was obsolete and provided minimal operator feedback in the event of faults or problems. The replacement PPU control system performs the same basic sequence controls as the previous system, but provides a significantly improved man machine interface through a graphical touch screen to convey current status information, sequence faults etc. This achieves a more rapid conclusion to faults where regeneration sequences have halted.

The system consists of an Allen Bradley SLC500 PLC performing the sequence and algorithm run-time controls housed in a single panel (shown left). The panel also houses various barriers, PLC interface equipment and DCS digital and analogue cards to interface to the field instruments and to facilitate the transfer of status information between the DCS and the PPU control system. Status information is presented to the operator by a QuickPanel touch screen display. Tierney Strachan designed the replacement system to have two main control processes; a regeneration sequence that controls the movement of routing valves and checks that the correct process conditions and time limits are met before advancing to the next stage, and a predictive runtime algorithm that calculates the maximum time the tower can remain online before reaching saturation. The runtime algorithm calculates an ongoing CO2 average by referencing a lookup table of run-time versus average CO2 content. The lookup table consists of 8 values of run-time stored for 8 values of CO2 in separate data files for each tower. A spline-curve fit is used to interpolate between the points. The average CO2 content is then used to predict the saturation time for the online tower.