Projects - Alwyn Fire Pump Upgrade

Tierney Strachan provides bespoke software and interface to third party Unit Control Panel as a result of replacement of existing Fire Pump equipment on Total North Alwyn platform.

Due to the expansion of the North Alwyn facilities since it was first installed, the platform required an extension of the firewater ring main. A study carried out by Total confirmed that though the existing pumps could meet the requirement there was a small margin between the operating point and the minimum operating point. In addition, the long term support of the existing diesel engine driver and its ancillaries was therefore in doubt due to equipment obsolescence.

There were initially four diesel driven fire pump packages on the Alwyn installation, two pump packages were located on NAA and two units on NAB. It was proposed to replace all four packages on the installation with new diesel driven fire pump packages (pump, gearbox, diesel engine, ancillaries and controls).

Each fire pump was supplied with a Unit Control Panel (UCP) which allowed for local control and observation, but it was also necessary for each pump to be controlled remotely using the existing platform PCS. This required the installation of 4 additional serial links to handle the transfer of data between the systems, in addition to the hardwired I/O which was connected direcltly to the platform PCS.

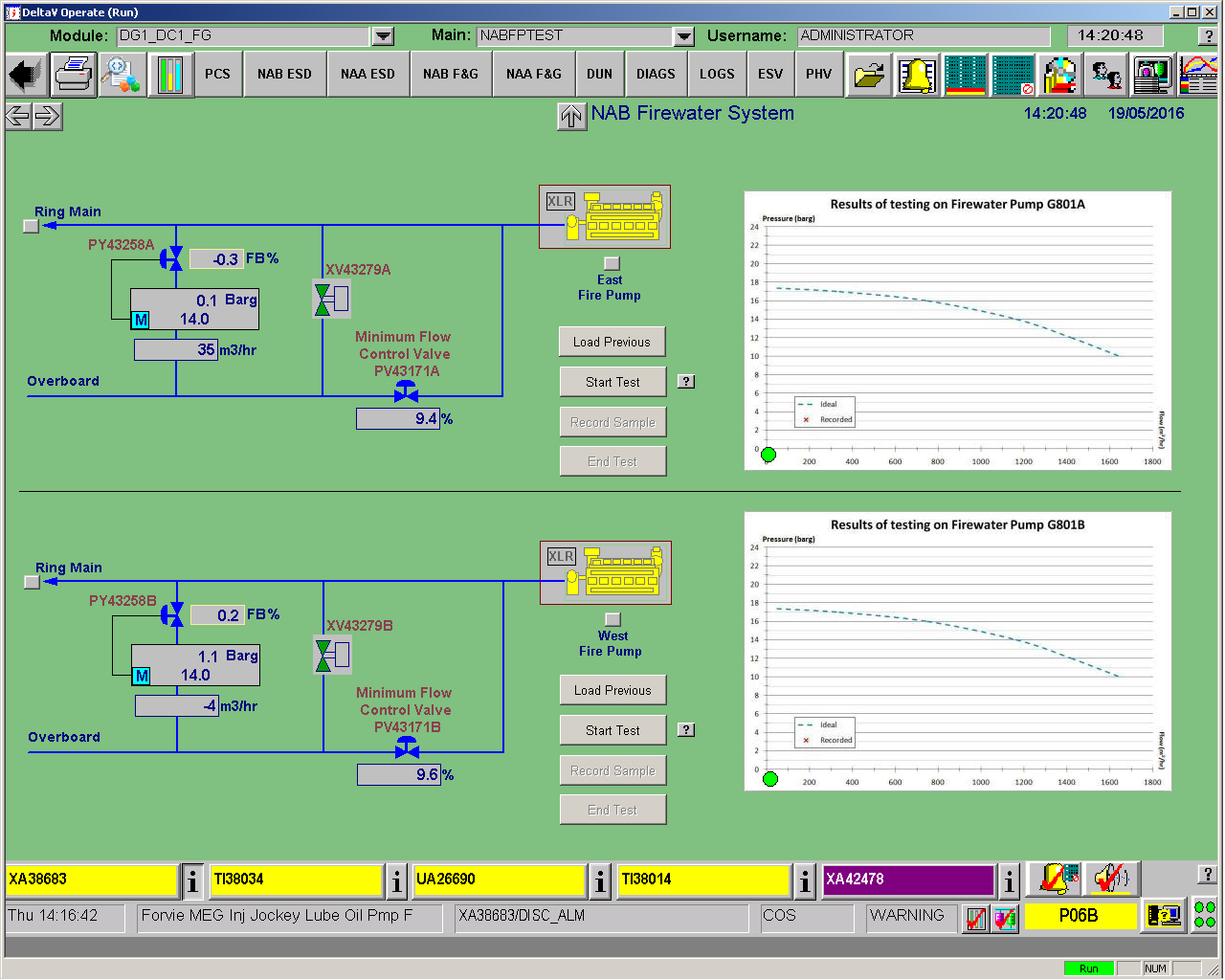

As part of the upgrade, Total made the decision to automate a considerable part of the biannual testing procedure for the fire pump system. Tierney Strachan was able to provide a system where the system operating point could be plotted on a graph and compared to an ideal curve, along with the ability to record the relevant data in an Excel spreadsheet for retrieval and review at a later date.

As the project covered both PCS and F&G modifications, and with the DeltaV PCS acting as the HMI for the F&G system, Tierney Strachan worked closely with the vendor for the platform F&G system to ensure all aspects of the design and implementaion were covered, including carrying out joint Factory Acceptance Tests (FATs).

Tierney Strachan provided the following as part of the scope:

- Project Management, drawings and documentation including Functional Design Specification (FDS) and Factory Acceptance Test (FAT) Procedure for review and approval;

- Supply of all equipment required to install the PCS functionality for the project, including terminals, wiring etc.;

- Design engineering for logic;

- Completion of client witnessed FAT to approved procedure;

- Installation of the PCS hardware and software on the North Alwyn platform;

- Site acceptance testing of the installed design.