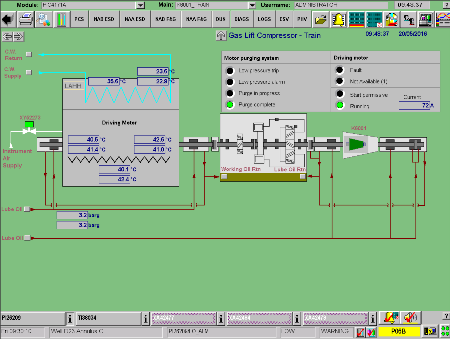

Projects - Gas Lift Compressor

Tierney Strachan provides design, build and testing of modifications to Alwyn PCS to support replacement of existing MGI system with new Gas Lift compressor, including building new control & I/O panel and interface to third-party UCP via serial link.

In order to improve production rates from the North Alwyn Brent wells, Total made the decision to replace the fixed speed Miscible Gas Injection (MGI) Compressor with a new artificial gas lift compressor, which utilised a 'Vorecon' mechanical variable speed drive.

The existing MGI compressor was controlled / shutdown via an ABB Advant PCS/PSD system. The new compressor was controlled / shutdown via a new Unit Control Panel (UCP) supplied by MAN Turbo Diesel, which used Siemens S7-400 series PLCs. To make space for the new UCP the existing ABB system was removed, and the remaining offskid instrumentation was migrated to the Platform PCS and ESD systems.

Tierney Strachan's extent of supply included the following:

- Supply of new cabinet, containing additional DeltaV controllers, I/O cards, relays, barriers and field terminals;

- Destruct of existing MGI compressor I/O from DeltaV PCS software and graphics;

- Configuration of new I/O within DeltaV PCS, and modification of graphics to include this;

- Modifications to existing data interface to platform ESD and F&G systems to add additional equipment (DeltaV graphics act as HMI for ESD / F&G systems);

- Addition of new dual-redundant serial link to third-party compressor UCP;

- Creation of additional graphics to replicate functionality of UCP on existing platform PCS;

- Creation of bespoke software within PCS to mimic functionality of logic being removed from ABB system;

- Full documentation covering all modifications; from Functional and Detailed Design documents and Interface Specifications through to Installation and Commissioning Procedures;

- Installation / installation supervision and field support for the duration of the commissioning.