Projects - Export Compressor Load Sharing

Tierney Strachan implements control scheme to handle load sharing between export compressors on Total North Alwyn platform.

The North Alwyn export compressors (K201A/S) were originally configured such that one ran fully loaded at any time, with the other taking up the slack, i.e. they were originally designed as two 100% compressors operating in a "running and standby" configuration. However over the years extra facilities were added on to the north Alwyn platform to allow the Dunbar, Nuggets and Forvie fields to be produced. These extra facilities meant that there was no longer enough capacity within the system when only running one of the export compressors, and both compressors were required to run in parallel.

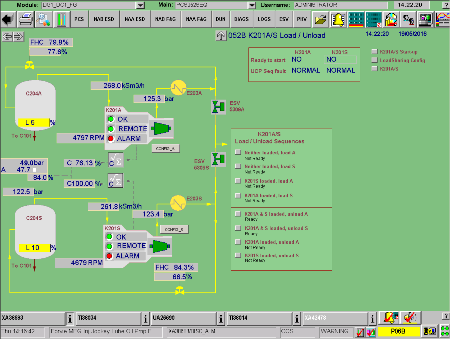

The compressors went through a control systems upgrade (involving new anti-surge controllers) and as part of that upgrade, load sharing control was implemented from the DeltaV PCS in 2008. A follow up to the original project in 2009 refined the control and added more configuration parameters.

The control scheme (developed by Xodus and implemented in the DeltaV PCS by Tierney Strachan) provided the following functions:

- Carrying out capacity control via speed modulation during single and dual compressor operation;

- Carrying out loadsharing when operating two compressors in parallel;

- Carrying out loading and unloading of each compressor with minimal operator input;

- Installed anti-stonewall type controller which would be activated when a jet/Turbine/gearbox/compressor vibration probe alarms.

The load sharing logic was implemented via a series of cascading PID controllers with sequences to perform the loading/unloading of the compressors.

The aim of the loadsharing controllers was to operate both compressors equidistant from the surge line. To achieve this, the DEV (distance from the surge line) was taken from anti-surge controllers, and routed to new master performance controller. The average DEV was then calculated and sent as the setpoint to each loadsharing controller.

Each loadsharing speed controller also received the raw DEV from the respective anti-surge controller and this acted as the controllers' PV. A normal PID algorithm calculated the loadsharing controller output which was then scaled before being added to the master performance controller output. The "total" outputs; i.e. loadsharing + performance, were then sent to each compressor speed controller, which would operate as per the previous (single active compressor) setup.

Within the control scheme there was also a discharge pressure override controller that would slow the compressors down if the discharge pressure increased above its limiting setpoint.